Liebherr Undercarriage

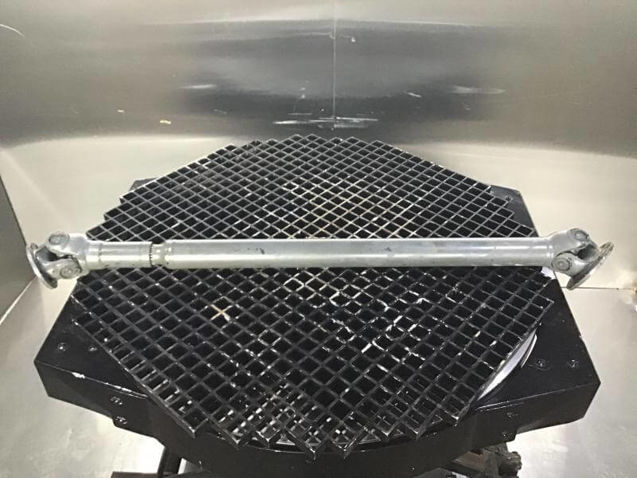

Used Liebherr undercarriage

The undercarriage of a Liebherr excavator forms the foundation of the machine, ensuring mobility and stability. The choice of undercarriage depends on the terrain where the excavator will be used. For greater freedom of movement, a wheeled undercarriage is the best option, while a crawler undercarriage is better suited for rough terrain.

Wheeled undercarriage

A wheeled undercarriage is ideal for excavators frequently operating on paved surfaces, such as at waste processing facilities or scrapyards. This undercarriage uses wheels and tires, which are the parts that wear out the fastest in such configurations.

Solid rubber tires

Solid rubber tires are made of solid rubber and are therefore puncture-proof. These tires are commonly used on excavators operating in environments with sharp objects on the ground, such as landfills. However, their drawbacks include weight, lack of suspension, and unsuitability for road use. Solid rubber tires are highly durable but may develop cuts or cracks over time.

Air-filled tires

Air-filled tires are a lightweight alternative for Liebherr excavators, offering greater mobility and comfort due to their cushioning effect. These tires are road-legal, unlike solid rubber tires. However, they are prone to punctures.

Crawler undercarriage

A crawler undercarriage allows an excavator to traverse difficult or rugged terrain. Tracks provide increased ground contact, ensuring better grip, preventing the machine from sinking, and minimizing soil compaction by distributing the machine's weight. For uneven terrain, muddy conditions, or steep slopes, tracks are indispensable. The crawler undercarriage consists of the following parts:

- Upper roller

- Track guide

- Idler

- Lower roller

- Chain

Wear on a Liebherr undercarriage

Despite being made of solid steel, parts will wear out over time. The drive system, chains, links, and guides often loosen due to wear. The springs in the rollers may fail, preventing the chain from maintaining tension. Chains and plates are particularly prone to wear. Over time, chains, which should remain round, can become oval, indicating they need replacement. Given their steel construction, used parts are a cost-effective alternative to new ones.

Undercarriage parts

In addition to tracks and tires, other components are available for the undercarriage of a Liebherr excavator. For instance, stabilizer legs can be added for increased stability when stationary. A dozer blade can also be attached for additional earth-moving capability, protection, and stability.

Delivery of Liebherr spare parts

We understand the urgency of replacing worn parts for your Liebherr machine. That’s why we ensure orders placed before 12:00 PM are shipped the next day.

Prices for Liebherr parts

Buying used parts for a Liebherr undercarriage offers many advantages. We maintain a large inventory and likely have the part you need in stock. Another major benefit is the cost—you can save up to 60% compared to new parts. As always, our used parts are of the highest quality.